Innovative Applications of Polypropylene

Polypropylene (PP) is a versatile thermoplastic polymer that has become a cornerstone material in the manufacturing of consumer goods. Its ability to be molded into a variety of shapes and its properties—such as light weight, resistance to chemicals, and durability—make it an attractive choice for many industries. In the consumer goods sector, polypropylene is increasingly being used in innovative ways to create products that are both functional and environmentally friendly. In this blog post, we’ll explore some of the most exciting and innovative applications of polypropylene in the consumer goods industry, highlighting how this material is shaping the future of consumer products.

1. Packaging Solutions for Sustainability

Polypropylene is a popular choice for packaging due to its strength, transparency, and resistance to moisture, chemicals, and UV radiation. However, its true innovation lies in how it is being used to address the growing demand for sustainable packaging solutions. With rising concerns about plastic waste and environmental impact, manufacturers are increasingly turning to polypropylene for eco-friendly packaging alternatives.

One example is the use of polypropylene in producing recyclable and biodegradable packaging. PP is already highly recyclable, which makes it a better alternative to other plastics like polyethylene (PE) or polystyrene (PS). Moreover, recent advancements in chemical recycling technologies are allowing polypropylene to be reused and repurposed into new products, closing the loop and reducing waste. For example, companies like Unilever and Coca-Cola have started using PP for beverage bottles and food containers, not only due to its durability but also for its recyclability, making it a key material in their efforts to achieve sustainable packaging goals.

Polypropylene is also playing a role in reducing plastic waste through the development of compostable packaging. Scientists are working on biodegradable versions of PP, incorporating additives that help the material break down more quickly in a composting environment. This allows consumers to dispose of their packaging more responsibly and reduces the environmental impact of plastic waste.

2. Textiles and Clothing: A Sustainable Approach

The textiles industry is another area where polypropylene is making waves, especially with the growing demand for more sustainable and eco-friendly materials. Polypropylene fibers are lightweight, moisture-wicking, and highly durable, making them ideal for a wide range of textiles. Polypropylene’s unique properties also allow for better performance in clothing, especially in outdoor wear and activewear.

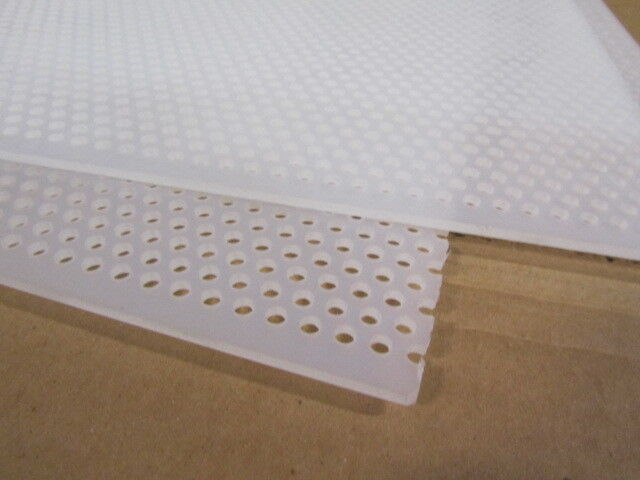

One key innovation is the use of polypropylene in non-woven fabrics, which are now commonly found in hygiene products such as diapers, feminine hygiene products, and medical supplies. Polypropylene-based non-wovens are lightweight, absorbent, and soft, offering a comfortable and efficient solution to these essential consumer goods.

Moreover, polypropylene is being used in the fashion industry for creating eco-friendly clothing and accessories. Many brands are exploring the use of recycled polypropylene fibers to create garments, shoes, and bags. This practice not only helps reduce the consumption of virgin materials but also contributes to the circular economy by reusing plastic waste and turning it into fashionable products.

3. Innovative Household Products

Polypropylene’s durability and versatility are making it an essential material in the production of household goods. The material’s resistance to heat and chemicals makes it ideal for use in products that experience frequent wear and tear, such as kitchenware, storage containers, and furniture.

In kitchenware, polypropylene is increasingly used to create food containers, microwave-safe plates, and utensils. Unlike other plastics, polypropylene can withstand higher temperatures without melting or releasing harmful chemicals, making it a safe choice for food-related products. Additionally, PP’s resistance to stains and odors means that kitchen products made from this material are more hygienic and durable, offering a long-lasting solution for consumers.

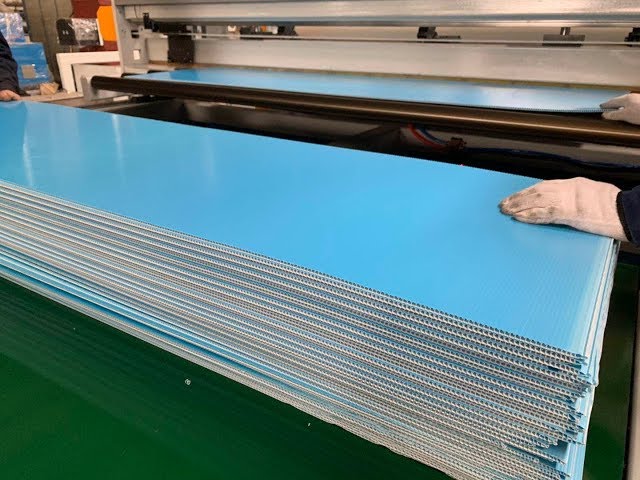

For storage solutions, polypropylene is a popular choice for producing bins, boxes, and shelving units. Its lightweight nature makes these products easy to handle and move, while its strength ensures they can hold heavy loads without cracking or breaking. The versatility of polypropylene also allows for creative designs that can cater to different household needs, from organizing home offices to creating custom closets.

Another area where polypropylene is making an impact is in the development of furniture, particularly modular and stackable pieces. The material’s ability to be molded into various shapes and forms makes it perfect for creating modern, flexible furniture options that are not only stylish but also functional and easy to assemble.

4. Personal Care and Hygiene Products

The personal care industry has long relied on polypropylene for its many benefits. The material is commonly used in the production of packaging for products like shampoos, soaps, lotions, and cosmetics. Its ability to be molded into different shapes, combined with its chemical resistance, makes it an excellent choice for storing a wide range of liquids and creams.

An exciting innovation in this area is the use of polypropylene in the development of refillable and reusable personal care products. Many brands are creating sustainable alternatives to single-use plastic bottles by offering refillable containers made from polypropylene. These containers can be reused multiple times, with the consumer simply purchasing refills in more eco-friendly packaging. This trend aligns with the growing demand for more sustainable consumer goods and supports efforts to reduce plastic waste.

Polypropylene is also used in the production of wipes and facial tissues, with nonwoven PP fabrics being widely used for their softness, absorbency, and durability. This has opened new opportunities for eco-conscious consumers, with brands now offering biodegradable or compostable wipes made from polypropylene.

5. Automotive Accessories for Consumer Goods

Polypropylene has found its way into the automotive industry, where it is used in a variety of consumer-facing products. Car accessories such as floor mats, seat covers, and dashboard components are commonly made from polypropylene due to its high resistance to wear and tear, as well as its lightweight nature.

Innovations in automotive design are also seeing more uses for polypropylene in custom car interiors, including components like door panels, trim pieces, and storage compartments. PP’s ability to be molded into intricate shapes and its long-lasting durability make it an ideal material for manufacturers aiming to provide cost-effective yet premium-feeling interior elements.

Moreover, polypropylene is being used in the production of car parts designed to enhance comfort and safety. For instance, car seat cushions made from polypropylene provide a lighter alternative to traditional foam materials, reducing the overall weight of the vehicle and improving fuel efficiency. Additionally, polypropylene’s heat resistance and flame-retardant properties ensure that these products meet safety standards without compromising on comfort.

6. Electronics: Lightweight and Impact-Resistant Components

In the electronics sector, polypropylene is being used in innovative ways to create lightweight, durable, and cost-effective components. From smartphone cases to laptop housings, polypropylene offers a unique combination of strength, flexibility, and resistance to heat, making it an ideal material for various consumer electronics.

The use of polypropylene in electronics is particularly notable in the production of protective casings and covers for devices like smartphones, tablets, and laptops. Due to its impact resistance, polypropylene ensures that electronic devices are well-protected against accidental drops and scratches while keeping the overall weight of the product low.

Additionally, polypropylene is being used in the production of battery cases for electric vehicles (EVs) and other power storage systems. These components need to be lightweight, durable, and able to withstand the demanding conditions that come with energy storage applications. Polypropylene’s impressive range of properties makes it an ideal material for such products.

Conclusion

Polypropylene continues to play a pivotal role in the consumer goods industry, driving innovation across a wide range of sectors. From sustainable packaging solutions to eco-friendly textiles, household products, personal care items, and automotive accessories, polypropylene’s versatility, durability, and sustainability make it an ideal material for modern consumer products. Companies seeking reliable materials for these applications often turn to a trusted PP Sheet supplier Singapore, known for providing high-quality polypropylene solutions. As the demand for more sustainable and functional products continues to grow, polypropylene’s applications are only expected to expand, shaping the future of the consumer goods industry for years to come.